WELCOME TO REACON

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

Product Description:

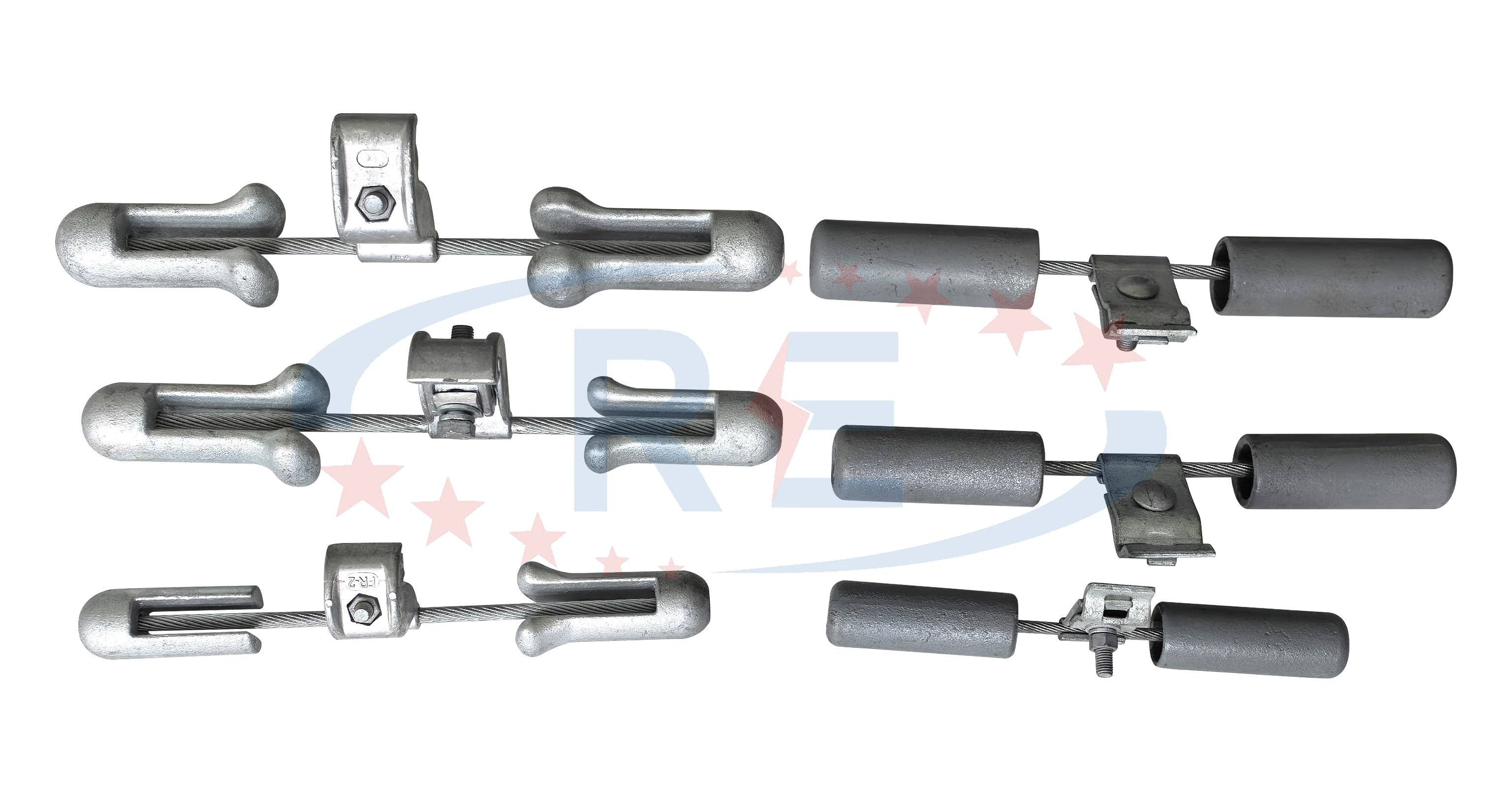

The Overhead Line Accessories Vibration Damper is specifically engineered to reduce vibration and protect conductors in transmission and distribution systems. Wind-induced oscillation can weaken fittings, loosen hardware, and cause fatigue damage to overhead cables. This vibration damper offers a reliable solution by absorbing mechanical vibration and minimizing stress at suspension points. Built with durable, corrosion-resistant materials, it ensures long-term stability in various outdoor environments, making it suitable for medium- and high-voltage power lines.

Product Advantages:

Effectively reduces wind-induced vibration on overhead conductors

Durable structure suitable for harsh field conditions

Compatible with multiple cable sizes and installation configurations

Low maintenance and long operating lifespan

Enhances service reliability of transmission infrastructure

Application Scenarios:

The Overhead Line Accessories Vibration Damper is widely used in:

High-voltage transmission lines – Installed on conductors to prevent fatigue caused by continuous vibration.

Distribution line networks – Used to stabilize cable spans and ensure consistent operational safety.

Coastal and high-wind regions – Helps minimize vibration caused by strong airflow and turbulence.

Mountain or valley terrain installations – Reduces conductor movement caused by uneven airflow.

Utility maintenance and upgrade operations – Ideal for replacing worn or outdated anti-vibration accessories.

Frequently Asked Questions:

Q1: What type of cables are compatible with the vibration damper?

A1: It can be used with different conductor sizes depending on the installation specification.

Q2: Does the damper require periodic maintenance?

A2: Minimal maintenance is needed due to its corrosion-resistant construction.

Q3: Can it be used in high-wind or coastal climates?

A3: Yes, it performs well in harsh weather and coastal applications.

Q4: Is installation complicated?

A4: Installation is straightforward and follows standard overhead line hardware mounting procedures.