WELCOME TO REACON

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

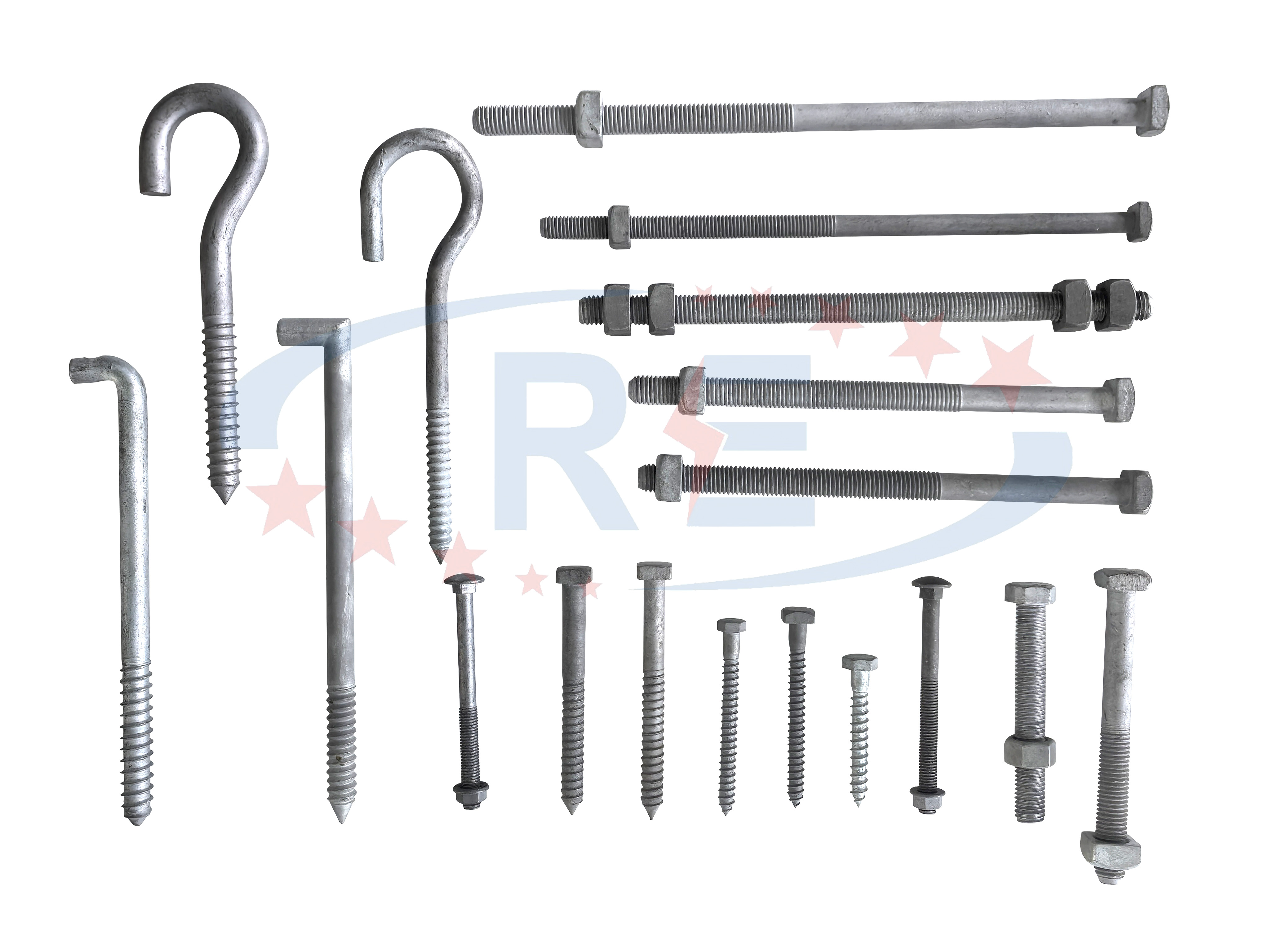

These heavy-duty hot dip galvanized lag screws are engineered for demanding structural wood connections where high tensile strength and long-term corrosion resistance are required. Manufactured from high-strength steel and finished by hot-dip galvanizing, the hot dipped galvanized timber lag screw provides a thick, adherent zinc layer that protects the fastener in outdoor, coastal, or industrial environments. Designed with deep coarse threads and a heavy shank, these lag screws deliver superior pull-out resistance for timber beams, posts, and heavy timber assemblies used in decks, poles, bridges, docks, and retaining structures.

Thick hot-dip galvanized coating gives long-term corrosion protection for the lag screws for structural wood connections.

High tensile core and optimized thread profile deliver exceptional pull-out and shear resistance.

Coarse deep threads ensure fast embedment and secure grip in soft and hardwood species.

Available lengths and diameters to suit a wide range of structural timber applications.

Compatible with washers and nuts for through-bolted or heel-in connections.

Decks, Pergolas & Outdoor Timber Framing

How to apply: Pre-drill pilot holes (typical diameter 70–85% of minor diameter for hardwood; 60–75% for softwood), insert the galvanized lag screw, tighten with appropriate torque using impact wrench or socket — use a large washer under the head to spread bearing load for structural connections.

Pole, Post and Anchor Connections

How to apply: For post-to-concrete or post-to-post assemblies, use through-bolting where possible — pass the lag through the member with washer and nut on the opposite side; hot-dip galvanized surface prevents corrosion at exposed edges.

Timber Bridges, Walkways & Structural Joists

How to apply: Use larger-diameter heavy-duty lag screws at shear and bearing points; arrange staggered rows of lag screws to reduce splitting — plug holes with waterproof filler if required.

Marine Piers, Docks & Coastal Timber Works

How to apply: Specify marine-grade hot dip galvanizing and consider tinned/stainless options for severe marine exposure; use neoprene or rubber washers to prevent crevice corrosion where metal meets treated timber.

Retaining Walls, Heavy Timber Frames & Structural Repairs

How to apply: Combine lag screws with timber plates or steel reinforcing plates for distributed load transfer; for repair work, remove damaged fasteners and replace with same or larger diameter hot-dip galvanized lag screws to restore capacity.

Each batch of hot dip galvanized lag screws undergoes raw-material traceability, mechanical tensile and shear testing, thread profile inspection, and galvanizing thickness measurement. Galvanization is performed by hot-dip process to industry corrosion standards (e.g., ASTM A153 or equivalent) to ensure a robust zinc layer. Dimensional conformity, coating adhesion and accelerated corrosion (salt-spray) tests are part of the QA protocol to guarantee consistent durability for structural wood connections.

Q1: Do I need to pre-drill pilot holes for these lag screws?

A1: Yes — pilot holes reduce splitting and provide correct seating. Typical pilot diameter: hardwood ≈ 70–85% of minor diameter, softwood ≈ 60–75%.

Q2: Are hot-dip galvanized lag screws suitable for coastal/marine projects?

A2:Yes — hot-dip galvanizing gives strong corrosion protection. For severe marine exposure consider higher-grade coatings or stainless/tinned options.

Q3: How do I choose screw diameter and length for structural joints?

A3: Select diameter to meet tensile and shear requirements (common structural sizes: 1/2”, 5/8”, 3/4” etc.); length must fully engage into the receiving member with sufficient embedment (typically ≥ 6–8× diameter for heavy loads). Follow project structural calculations or manufacturer guidance.

Q4: Can these lag screws be used with pressure-treated timber?

A4: Yes — but ensure fastener metallurgy (hot-dip galvanizing) is compatible; some treatment chemicals accelerate corrosion so select appropriate coating or stainless alternatives.

Q5: What maintenance is required?

A5: Minimal — inspect periodically for corrosion, loosening, or wood degradation; re-tighten or replace fasteners showing significant corrosion or loss of clamp load.