WELCOME TO REACON

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

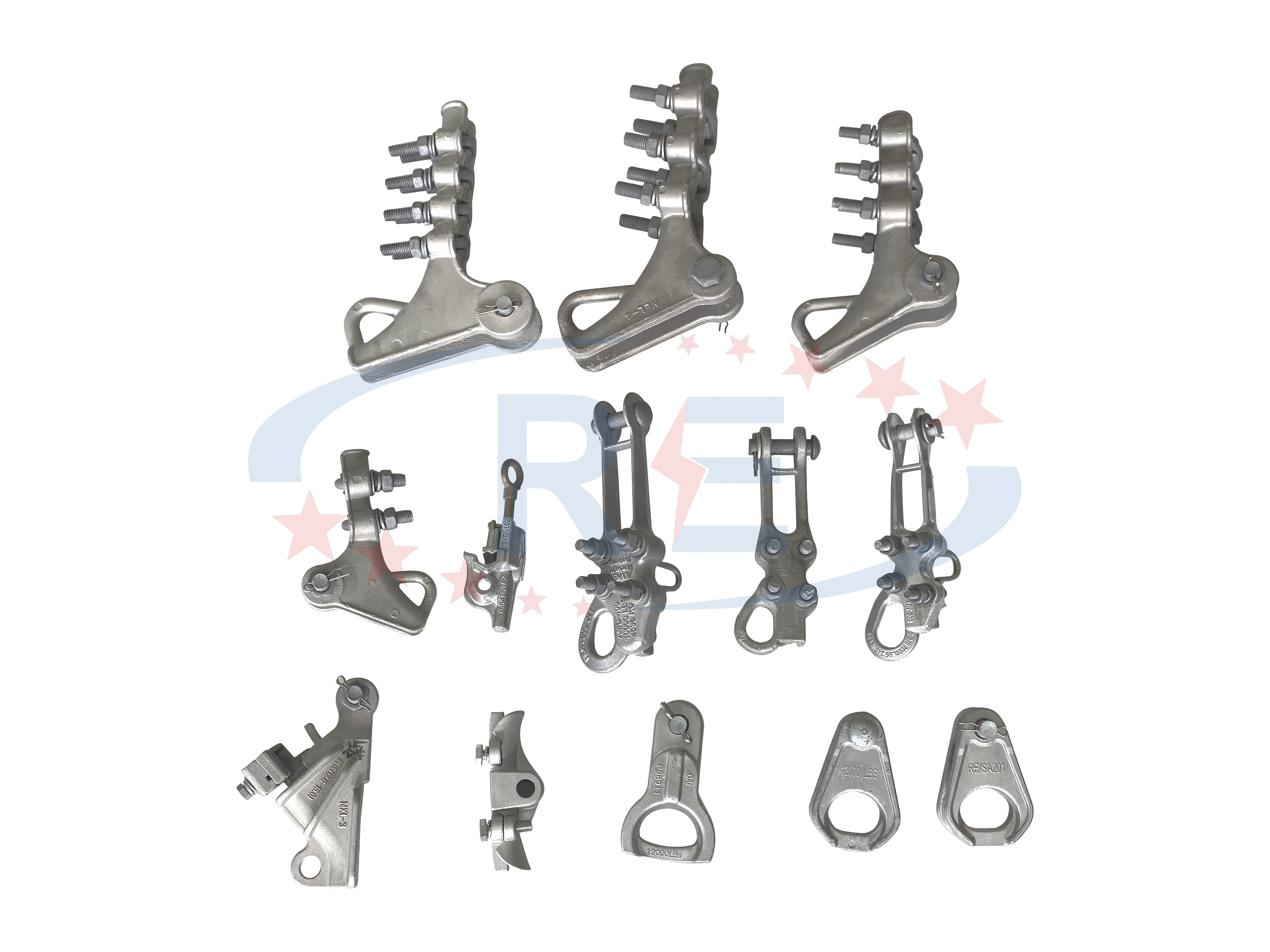

The Aluminum Alloy Strain Clamp is a high-strength tension fitting designed for securing conductors in overhead lines, distribution networks, transmission systems, and ADSS/OPGW applications. Manufactured using premium-grade aluminum alloy with a hot-dip galvanized steel body and hardware, this Aluminum Alloy Strain Clamp provides dependable grip strength, excellent corrosion resistance, and long-term stability under outdoor environmental exposure. It ensures reliable conductor support and prevents slippage during tensioning, making it suitable for long-span lines, power infrastructure projects, and harsh climates. The Hot-Dip Galvanized Tension Fitting for Overhead Lines offers outstanding fatigue performance and compatibility with standard pole line hardware, making it a widely used fitting in power utilities.

High mechanical strength with secure gripping performance

Excellent corrosion resistance due to hot-dip galvanized finish

Lightweight yet durable aluminum alloy construction

Compatible with overhead line accessories and tensioning devices

Long service life suitable for extreme outdoor environments

Overhead Power Transmission Lines

Used to maintain conductor tension and prevent sagging in long spans.

Distribution Networks

Ensures stable tension for insulated and bare conductors.

ADSS & OPGW Installation

Provides reliable anchoring for fiber cable deployment.

Position conductor into the Aluminum Alloy Strain Clamp, apply tension with a tensioning tool, then secure using bolts and galvanized hardware.

Manufactured according to IEC, IEEE, and ASTM pole line hardware standards

Tensile, fatigue, and salt-spray resistance testing completed

Each batch includes traceable inspection certification

Guaranteed long-term reliability under field conditions

Q1: Can the Aluminum Alloy Strain Clamp be used in coastal or corrosive environments?

A1: Yes, the aluminum alloy and hot-dip galvanized steel provide excellent corrosion resistance.

Q2: Is it available in multiple conductor sizes?

A2: Yes, customized sizes based on conductor type are available.

Q3: Does it require special tools for installation?

A3: Standard tensioning tools are recommended for best performance.