WELCOME TO REACON

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

Product Description:

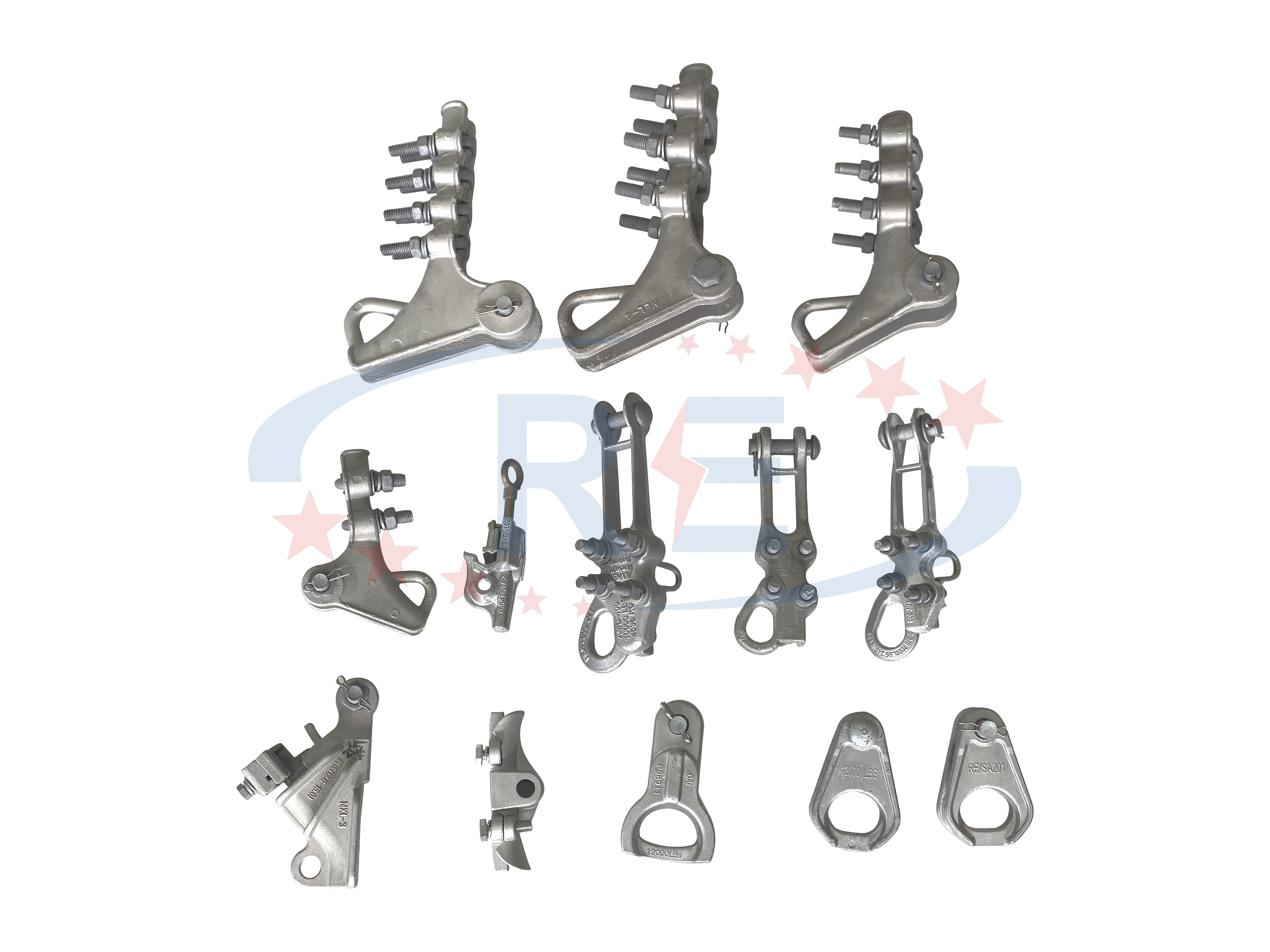

The Clamp, Hot Line E 1030-AGP is designed for secure live-line connections in overhead power distribution systems. Its robust construction and precision grip design ensure a strong and reliable electrical interface while minimizing conductor wear during installation. Compatible with hot-stick tools, this hot line clamp allows linemen to complete safe and efficient live connections without service interruption. The corrosion-resistant body material ensures long-term stability in outdoor and high-moisture environments.

Product Advantages:

Designed for live-line installation with standard hot-stick tools

Strong holding force ensures stable electrical contact

Corrosion-resistant structure suitable for harsh environments

Compatible with multiple conductor sizes

Reduces downtime and improves operational efficiency

Application Scenarios:

The Clamp, Hot Line E 1030-AGP is commonly used in:

Live-line repair and maintenance – Enables safe replacement or tightening of connections without power shutdown.

Overhead distribution networks – Installed to secure conductor joints and maintain stable power flow.

Emergency utility response – Supports fast restoration procedures after storm or equipment damage.

Grid expansion or line upgrades – Allows continuous operation while adding new connections.

Coastal, industrial or corrosive environments – Ideal due to its long-term resistance to oxidation and corrosion.

Parameter:

Safety & Quality Assurance:

Inspected for electrical conductivity and mechanical strength

Manufactured under strict quality control procedures

Suitable for high-voltage, live-line use

Hot-dip galvanized or aluminum alloy body for long service life

Compatible with industry standard tools and conductors

Frequently Asked Questions:

Q1: Can the clamp be installed while the power is energized?

A1: Yes, it is specifically designed for hot-line operation.

Q2: What conductor sizes are compatible?

A2: It supports multiple conductor types based on installation requirements.

Q3: Does the clamp require maintenance?

A3: Minimal maintenance is needed due to its corrosion-resistant materials.

Q4: Is specialized equipment required?

A4: Yes, hot-stick compatible tools are recommended for installation.